Applications

CommerciaL

Graphite, microchips, rechargeable batteries, cars, and more. The commercial applications of AmeriCarbon’s Eco-Pitchᵀᴹ yield as many permutations as carbon itself. Advanced carbon materials like carbon fiber and graphene nano-tubes are mere steps away through AmeriCarbon’s proprietary process.

Defense

Defense suppliers currently rely on foreign carbon imports to produce everything from lightweight personnel armor to radar-absorbing jet plating. AmeriCarbon’s supply is sourced in the US and ensures the American military is backed by an American enterprise.

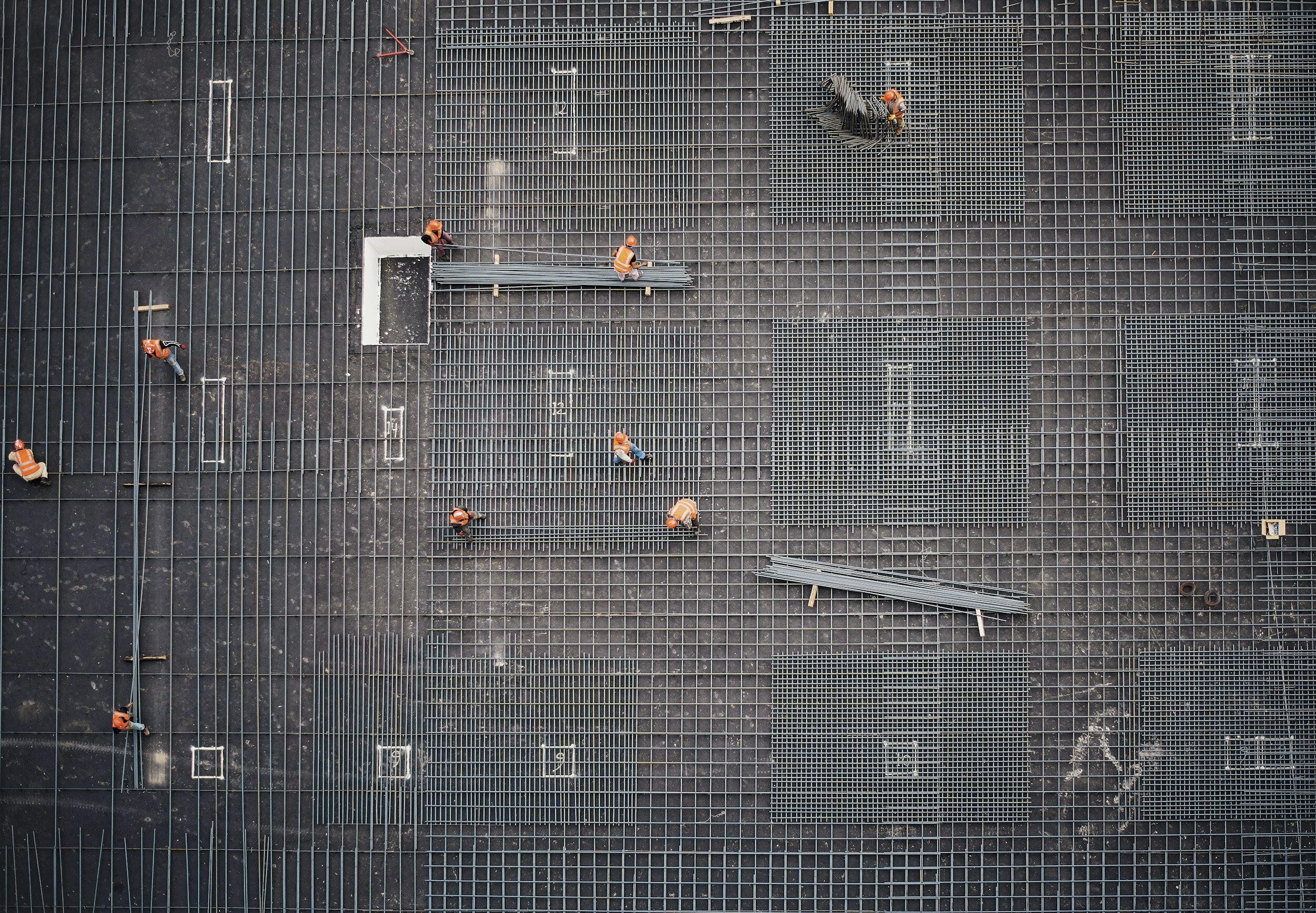

InFRASTRUCTURE

American infrastructure is pacing behind other nations and struggling to keep pace with the current rate of expansion. As Congress approves hundreds of billions in infrastructure spending, AmeriCarbon’s Eco-Pitchᵀᴹ offers a safe, cost-effective, and domestic alternative that paves the way for the future. Literally.

Our Process

Sourcing Raw Carbon Ore

We begin by sourcing raw carbon ore in the form of coal from Appalachia and other American sources. This lays the foundation for the manufacture of advanced carbon materials.

Eco-Pitchᵀᴹ Carbon Liquefaction

Through our patented Eco-Pitchᵀᴹ carbon liquefaction process, AmeriCarbon transforms coal into a versatile liquid form while also concentrating rare earth elements in an ash byproduct.

Tailored Coal Tar Pitch

In the tailoring process, the liquid carbon is converted into a customizable coal tar pitch, perfectly suited to meet the precise needs of buyers across various industries.

Our tailor-made coal tar pitch is sold to buyers who use it to craft a diverse array of advanced carbon materials, from high-performance batteries to radar-absorbing armor and specialty foams.

Carbon Materials

“onshoring our supply chain isn’t an option for national security - it’s a necessity.”

- Chairman of the Joint Chiefs of Staff, Gen. Charles Q. Brown, Jr.